A new engine concept for the diesel outboard marine market

Technical report for the ALFING company magazine:

No diesel outboard motors have been produced or sold since 2007.

The reason for the manufacturers’ strategic withdrawal were the strict emissions standards. The modernization of the up to 30 years-old designs would have meant major efforts in the adaptation or lengthy research and development of new engines.

The development of completely new engines, especially with a sophisticated turbocharger and complex diesel fuel injection technology, is not profitable for large long-standing marine engine producers. The investment for the development would be hardly amortizable.

The commercial marine engine market revolving mainly around 50 HP-engines only counts about 5,000 motors per year. This is no starting point for big organizations, but a perfect niche for a small, lean and innovative technology-driven company: In 2006 Neander Motors AG was founded and holds the property rights of the dual crankshaft in diesel engines in combination with the diesel combustion process.

After a careful market analysis the green light for the development of a 50 HP 800 ccm in-line, turbocharged, intercooled twin-diesel with dual crankshafts and common-rail injection in solid aluminium was given.

Why the complexity of dual crankshafts?

Amongst all reasonable two-cylinder concepts – Boxer-Twin, V-Twin, In-line-Twin with balance shaft – the two-cylinder with dual crankshaft arrangement provides the best dynamic properties.

Amongst all reasonable two-cylinder concepts – Boxer-Twin, V-Twin, In-line-Twin with balance shaft – the two-cylinder with dual crankshaft arrangement provides the best dynamic properties.

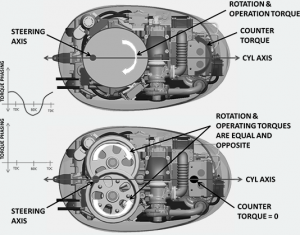

Thanks to the internal torque and shearing force compensation it is completely free of rolling moments. This is a prerequisite to assure that the outboard engine runs smoothly without the transmission of irritating rotating moments from the tiller to the users’ hands.

In addition to the absence of vibrations the compensation of the oscillating force, 1st order, is 100% representable as mass side forces are compensated by the counter-rotating dual crankshafts. This makes it the perfect drive for the commercial outboard sector where users often are in the field for 8 hours or more. Here they can operate and drive the boat without tiring.

As a consequence of the dual crankshaft design another invention was needed: the spaceball.

In this the two connecting rods are mounted conventionally over two relatively small piston pins while the spaceball can perform rotation motions within the piston. This results in the necessary degree of rotational freedom, which compensates or even prevents misalignment of the piston within the cylinder due to component and manufacturing tolerances completely.

All other construction and design principles are conventional and have been derived from construction methods of high-performance engines, so that despite the relatively small specific crankshaft output of 50 kW/l excellent robustness for the commercial sector is achieved. The crankshaft output is about 5-8% higher than that measurable at the propeller shaft or than the actual outboard output itself.

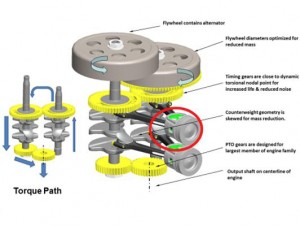

The motor with the bedplate and closed deck crankcase is screwed to the two-part cylinder head with tie rods. The main bearing area is reinforced by moulded-in steel straps to ensure constant tolerance in the gear connection of the two counter-rotating crankshafts under thermal expansion.

The motor with the bedplate and closed deck crankcase is screwed to the two-part cylinder head with tie rods. The main bearing area is reinforced by moulded-in steel straps to ensure constant tolerance in the gear connection of the two counter-rotating crankshafts under thermal expansion.

Two flywheels are necessary, in order to systematically keep the dynamic gearing moments over the zero-crossing while in operation. This provides the best possible acoustics of such a spur-geared drive.

ALFING crankshaft are made of the material 42CrMo4.

With a 45 mm main and 42mm connecting rod bearing pin diameter with a piston stroke of 80 mm they are constructed fairly rigid with regard to bending and torsion. Only half of the piston force goes into a crank journal. Therefore the maximum torsion angle only amounts to 0.18 degree at 4000 1/1min.