Research and mechanical optimization at the Technical College of Applied Sciences, Munich

The laboratory for combustion engines at the Technical College of Applied Sciences, Munich and the company BMR from Geretsried have been NEANDR’s key partners since the development of the worldwide first turbo diesel motorcycle.

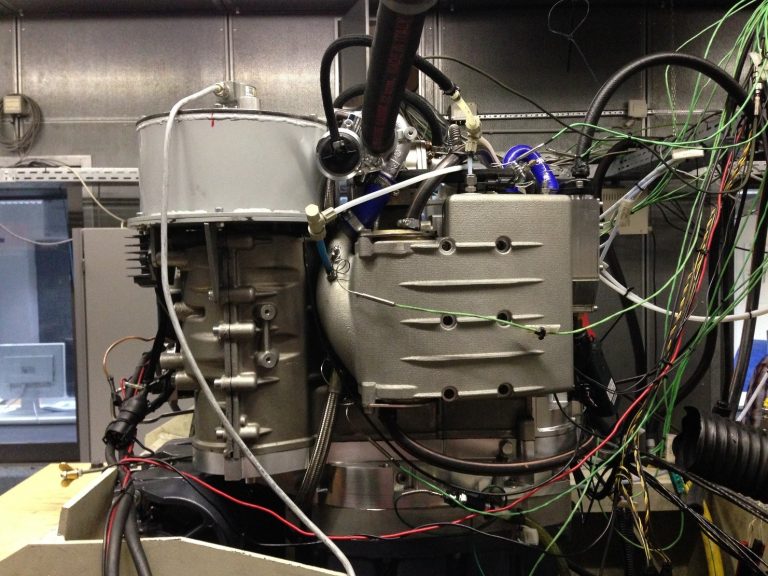

Several designs made by BMR – who also manufactures some of our prototype parts – have been and are still being exclusively tested in close cooperation with the Technical College in Munich. Specifically for the NEANDER turbo diesel outboard engine a dynamometer with a water basin was installed. The knowledge obtained is mostly incorporated into the series production.

At the test bench engine extensive measurement equipment was applied so that e.g. the calibration for the engine’s electronic control unit can be determined and to identify the drive’s executable configuration. Moreover further components (type of injectors, revised water circulations, optimized lubrication, engine ventilation etc.) are being continuously tested and optimized. Acoustic measurements help to determine the total noise level and to locate and eliminate weak spots by means of resonance measurements.

Prior to release for the dynamic tests the latest mechanical parts of the outboard, but also many students of the Technical College are „tested“: Many graduates wrote their theses about different aspects concerning the NEANDER turbo diesel outboard. Furthermore the students are involved in the drive’s revisions at BMR so that they receive practical insights regarding the engine.

Thus this valuable cooperation brings benefits for NEANDER and the Technical College in Munich!